From layout to schematics, we offer custom conceptual PCB design services tailored to meet the unique requirements of each client. Our team possesses the expertise, innovation, and methodology necessary to deliver sustainable, high-performance end products. Leveraging years of hands-on experience across diverse industries, we consistently provide precise, scalable, and future-ready PCB solutions that stand up to real-world challenges.

At Verinoinfi, we fully understand the critical transition from prototype to mass production. Our process is rooted in meticulous attention to detail, ensuring every aspect of the design—from component selection to signal integrity—is optimized for success. We collaborate closely with our clients to align technical goals with practical applications, helping them reduce time-to-market and avoid costly rework.

Embedded Devices/Hardware

Power Electronics, Conceptual Design for Electronics circuit, Embedded based solutions, Embedded Hardware Support, Driver designing for different kinds of devices like Motor, Relay, Contactor, LED, Bulb, etc.

PCB Design and Manufacturing

Our experienced engineers can do complex PCB Design of multi-layer PCBs for multi-processor with proven design methodologies and quality checks. PCB Development and Fabrication.

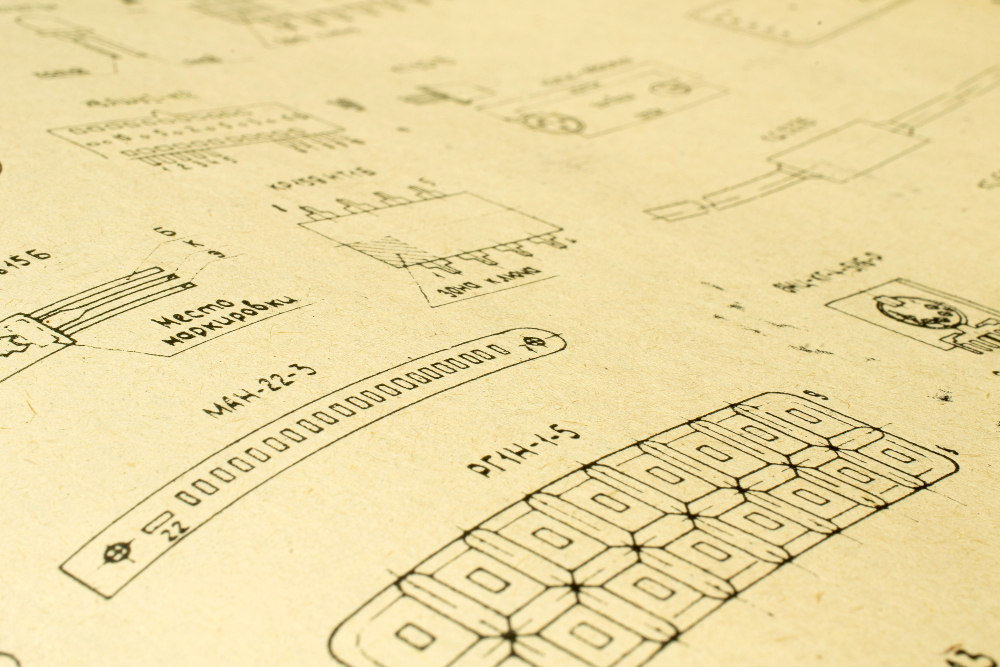

Schematic

Our team does Schematic design and data solidarity with the help of tools like OrCAD, Altium, etc.

Reverse Engineering

Innovations by reverse engineering analysis.

Our Process Flow From Conception to Mass Production

Our design approach is very organized to ensure satisfaction for our esteemed clients.

Customer Enquiry

Pen down all the details, and analyze if it evolves into potential business proposition.

Costing and Documentation

Costing, Non-Disclosure Agreement if needed and any other document.

Technological development

Includes Conceptual Design, testing and Reverse Engg. if needed.

Product Freezing

Final Design and testing of POC,Customer Approval

Production

PO generation, Trial Run, Final costing and Mass production

Additional Testing

Environmental testing, Reliability test report, LAB certification, Protection Testing etc.